The Magnet That Could Hold the Sun?-Inside ITER

For decades, scientists have dreamed of tapping into the same energy that powers the sun nuclear fusion. It’s the holy grail of clean energy: safe, nearly limitless, and with zero carbon emissions. But turning that dream into reality here on Earth is no small feat. That’s where ITER comes in.

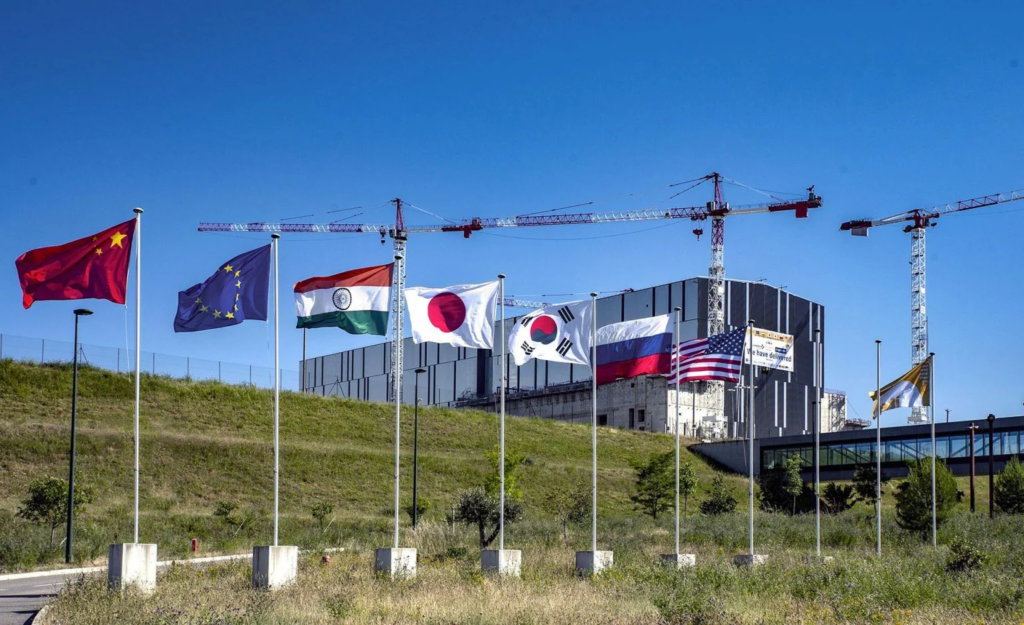

Located in southern France, ITER is the world’s biggest and boldest attempt to make fusion energy work. It’s a global effort, with over 30 countries teaming up pooling brainpower, tech, and resources to build this massive experimental reactor.

And now, there’s big news: ITER has finished building all the major parts of its gigantic superconducting magnet system. This isn’t just another milestone it’s a game-changer. After years of design and manufacturing, the project is finally shifting gears from building parts to putting it all together.

Finishing the magnet system is a huge win for the ITER team it means one of the toughest challenges is now behind them. It’s a clear sign of the dedication and engineering brilliance of the global team driving this project forward. More importantly, this milestone brings us one step closer to turning fusion energy from science fiction into reality. The dream of clean, sustainable energy is no longer just a distant hope it’s starting to feel within reach.

The Indispensable Role of Superconductors in ITER

At the core of ITER’s cutting-edge tech is something pretty wild superconductivity. When certain materials are chilled to mind- blowingly low temperatures about 4 Kelvin, or -269°C they lose all electrical resistance. That means electricity can flow through them with zero energy loss. To pull this off, ITER uses advanced liquid helium cooling systems to keep everything ice-cold.

But this isn’t just cool science it’s absolutely vital. Without superconductors, powering the enormous magnets needed to hold the ultra-hot fusion plasma would eat up more energy than the fusion could ever produce. Superconductivity makes it all possible, turning a near-impossible energy equation into something that might just work.

Superconducting magnets are the secret sauce behind ITER’s ability to hold plasma that’s hotter than the sun literally. We’re talking about temperatures around 150 million degrees Celsius, nearly 10 times hotter than the Sun’s core. To handle that kind of heat, ITER creates an “invisible cage” using insanely powerful magnetic fields. That’s where superconductors come in.

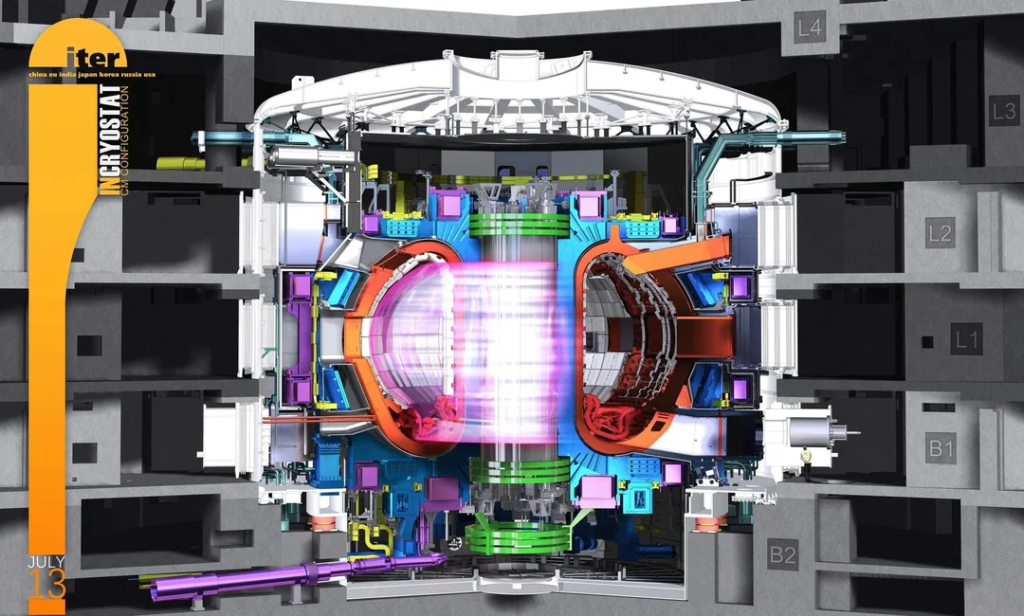

ITER’s magnetic system is like a carefully choreographed dance of different magnets, each doing a specific job. Eighteen giant D-shaped Toroidal Field (TF) coils are arranged like slices around the reactor. Their main job? Keep the charged plasma particles trapped in a loop. Then, there are six massive ring-shaped Poloidal Field (PF) coils wrapped around the outside. They help shape and stabilize the plasma kind of like giving it a gentle squeeze to keep it from hitting the reactor walls

At the heart of ITER’s magnetic muscle is the Central Solenoid (CS) think of it as the system’s backbone. It’s responsible for kick starting and maintaining the powerful electric current that flows through the plasma, keeping the fusion process alive.

Supporting it are eighteen smaller Correction Coils (CC), which act like fine-tuning knobs. They’re placed precisely to fix any tiny glitches or imperfections in the magnetic field, ensuring everything stays balanced and under control.

As for what these magnets are made of it’s all high-tech stuff. The Toroidal Field (TF) coils and the Central Solenoid use niobium-tin (Nb₃Sn), a superconductor that can handle extreme magnetic fields. Meanwhile, the Poloidal Field (PF) and Correction Coils use niobium-titanium (NbTi) not as intense, but perfect for the job they’re built to do.

Choosing the right superconducting materials for ITER wasn’t just a lucky guess it was a carefully calculated engineering move. Each type of magnet in the system has its own job, and that means different demands.

Niobium-tin (Nb₃Sn) is the heavyweight champ here. It performs exceptionally well under intense magnetic fields, which is exactly what’s needed for the Central Solenoid and Toroidal Field coils the parts doing the heavy lifting in plasma confinement and current generation.

By matching each material to its ideal role, ITER’s engineers created a magnet system that’s not just powerful but precisely optimized for fusion’s extreme conditions.

Central Solenoid: The Heart of ITER’s Magnet System

Big news recently: ITER has just finished building the sixth and final module of its Central Solenoid, a key component of the fusion reactor. This monumental piece was crafted and rigorously tested in the United States, thanks to the hard work of US ITER and General Atomics. Before it left the factory, it went through tough tests simulating the extreme conditions it’ll face at ITER. So far, four modules have already been delivered to the ITER site in France, stacked up and ready for assembly, with the fifth module on its way and the sixth module about to be shipped soon. And while the six main modules are complete, there’s still a seventh spare module in the works.

The Central Solenoid itself is an engineering masterpiece. Standing at an incredible 18 meters (59 feet) tall and weighing a whopping 1,000 tonnes, it’s designed to generate a magnetic field 13 Tesla strong 280,000 times the strength of Earth’s magnetic field. It’ll store an insane 6.4 Gigajoules of energy and help generate a 15 Megaampere current in the plasma, lasting between 300 and 500 seconds. Each of its modules is made from about 6 kilometers of Niobium-tin superconducting cable (with the strands supplied by Japan) and will operate at a frigid 4.5 Kelvin (-269°C), kept cool by liquid helium.

Functionally, the Central Solenoid is the powerhouse of ITER’s magnet system, playing a huge role in heating and controlling the plasma for fusion. It works alongside the six Poloidal Field magnets to keep the plasma stable. To ensure the solenoid can handle the stresses of its extreme job, the United States also supplied a special “exoskeleton” support structure an intricate framework made of over 9,000 parts. This exoskeleton can withstand a force of up to 60 meganewtons, which is the same as twice the thrust of a space shuttle or enough to lift an aircraft carrier.

The sheer scale of this project and the forces involved show just how massive and challenging the task of harnessing fusion energy is. It’s not just about creating a magnetic field; it’s about creating something powerful enough to hold and control plasma at the heart of a fusion reaction.

| Feature | Specification |

| Height | 18 meters (59 feet) |

| Diameter | 4.25 meters (14 feet) |

| Weight | Approximately 1,000 tonnes |

| Magnetic Field Strength | 13 Tesla (280,000 times Earth’s) |

| Stored Magnetic Energy | 6.4 Gigajoules |

| Plasma Current | 15 MA (300-500 second pulses) |

| Superconducting Material | Niobium-tin (Nb₃Sn) |

| Cooling Temperature | 4.5 Kelvin (-269°C) |

A Global Symphony of Superconductivity: International Contributions

The ITER project is a shining example of global collaboration, with countries across the world coming together to make fusion energy a reality. A key piece of this international teamwork is the superconducting magnet system, where nations have contributed vital resources and expertise.

The United States has played a major role, building and testing all six modules (plus a spare) of the Central Solenoid and providing its crucial support structure, the exoskeleton. The US also supplied about 8% of the Niobium-Tin (Nb₃Sn) superconductors for the Toroidal Field (TF) magnets.

Russia contributed the 9-meter Poloidal Field (PF1) magnet and provided about 40% of the Niobium-Titanium (NbTi) for the PF magnets, along with a significant amount of Nb₃Sn for the TF magnets. Russia also provided important high-power busbars and vacuum vessel port plugs.

Europe has been instrumental, manufacturing four Poloidal Field magnets in France and producing key portions of the superconductors for both the PF and TF magnets. As the host nation, Europe is also covering nearly half the cost of ITER’s construction.

China has supplied about 65% of the Niobium-Titanium (NbTi) superconductors for the PF magnets and 8% of the Toroidal Field superconductors, plus 18 superconducting Correction Coils. China also plays a role in magnet feeders.

Japan delivered the 43 kilometers of Nb₃Sn superconductor strand used in the Central Solenoid modules and produced 8 Toroidal Field magnets. Japan also made 25% of the Nb₃Sn superconductors for the TF magnets.

Korea contributed 20% of the Toroidal Field superconductors, along with thermal shields, precision tooling, and four vacuum vessel sectors. Meanwhile, India is responsible for building the massive 30-meter-high cryostat housing the ITER reactor, and has provided key components like cryolines, cooling systems, shielding, and plasma heating elements.

| Nation | Key Contributions |

| United States | Central Solenoid (all six modules + spare), Central Solenoid support structure (exoskeleton), ~8% of Toroidal Field magnet superconductors |

| Russia | Poloidal Field magnet (PF1), ~40% of Poloidal Field magnet (NbTi) superconductors, ~20% of Toroidal Field magnet (Nb3Sn) superconductors, high-power busbars, vacuum vessel port plugs |

| Europe | Four Poloidal Field magnets, 10 Toroidal Field coils, substantial portion of Toroidal Field magnet (Nb3Sn) superconductors, five vacuum vessel sectors, worked with Russia on NbTi for PF magnets 1 & 6 |

| China | ~65% of Poloidal Field magnet (NbTi) superconductors, ~8% of Toroidal Field magnet superconductors, 18 Correction Coils, magnet feeders |

| Japan | Niobium-Tin (Nb3Sn) superconductor strand for Central Solenoid, 8 Toroidal Field magnets (+ spare), all Toroidal Field magnet casing structures, 25% of Toroidal Field magnet (Nb3Sn) superconductors |

| Korea | 20% of Toroidal Field superconductors, thermal shields, precision tooling, four vacuum vessel sectors |

| India | 30-meter-high cryostat, cryolines, cooling system, shielding, plasma heating elements |

The Significance of Completion for Fusion Energy’s Future

The completion of ITER’s superconducting magnet system marks a major milestone in the journey to unlock the power of fusion energy. This breakthrough brings ITER closer to its ultimate goal: creating a “burning plasma” a state where fusion reactions themselves generate most of the heat, leading to a net energy gain. ITER is designed to produce 500 megawatts of fusion power with just 50 megawatts of input, aiming for a tenfold energy gain. This puts us one step closer to a future powered by fusion, a clean, safe, and nearly limitless energy source that could help meet global energy demands and tackle the urgent challenge of climate change.

Fusion power offers major advantages: it doesn’t produce long-lived radioactive waste or greenhouse gas emissions. The fuel deuterium from seawater and tritium from lithium is virtually endless. Plus, fusion reactors are inherently safe, with no risk of a meltdown. ITER is an essential test bed, bridging the gap between laboratory research and real-world fusion power plants.

Overcoming Herculean Challenges: Engineering and Manufacturing Innovations

Building ITER’s massive superconducting magnets has been nothing short of a engineering feat, facing numerous challenges every step of the way. The scale of production alone has required huge quantities of specialized superconducting cable, and working with materials like Niobium-tin, which are complex and brittle, called for innovative fabrication methods. The entire process of creating these superconductors involves a multi-step, intricate procedure, and achieving the precision needed to wind and place the conductors in the magnets was a monumental task.

Testing these enormous magnets under real-world conditions was no less challenging, especially when you consider the extreme forces and temperatures they’ll face in operation. Keeping these superconductors working over the long term, despite thermal cycles, mechanical stresses, and neutron bombardment, was another major hurdle. To maintain the superconducting state, advanced cooling systems using liquid helium had to be developed to keep everything at cryogenic temperatures.

To tackle the cooling problem, scientists came up with the concept of “cable-in-conduit conductors”, where the superconducting cable is wrapped in a metal jacket, with a central channel for liquid helium to flow through, cooling the magnets from within.

Despite these huge challenges, the successful completion of the magnet system is a major milestone for the ITER project. It highlights the massive strides made in superconducting magnet technology and large-scale engineering. The lessons learned and the expertise gained here will be invaluable as we move closer to making fusion power a reality and building future fusion reactors.

ITER’s Journey and the Horizon of Fusion Energy

With the completion of the superconducting magnet system, ITER is steadily advancing toward its operational phase. The Tokamak assembly is already in progress, and the first phase of operations, aimed at achieving deuterium-deuterium fusion, is targeted for 2035. Following that, the goal is to reach full magnetic energy and plasma current operation. As ITER moves forward, there’s growing private sector interest in fusion energy. The project is actively collaborating with private companies to foster innovation and share its knowledge. Initiatives like workshops, including one in April 2025, and the release of ITER software under open-source licenses, are designed to encourage broader industry participation.

However, ITER’s journey hasn’t been without its challenges. The original goal of achieving first plasma by 2018 has shifted several times, with the new target now set for 2034. The project’s costs have increased, and technical and managerial hurdles have arisen along the way. Despite these setbacks, the successful completion of the magnet system demonstrates the continued international commitment to realizing fusion energy. The growing involvement of the private sector signals an increasing recognition of the need for diverse approaches and potentially faster timelines in making fusion power a reality.